Test Benches

We have developed a wide range of test benches, made on customer request for specific applications. The main sectors are Automotive and low voltage Electricity. Often the test automation is integrated with the assembly of the components.

Test bench for motor controls of circuit breakers

Bench for testing the opening and blocking functions of circuit breakers. The benches can be customized on the basis of customer needs.

Test bench for motor controls of circuit breakers

The bench is equipped with a Keyence vision system for checking the correct signal graphic of the trip condition of the engine control lever.

The engine power is checked by a special electronic card.

To check the closing and opening times on 4 and 9 channels, special fast inputs will be set up on the PLC.

The bench is managed by an ASUS touch screen PC with HMI function, which hosts a software internally developed that allows the following functions:

- Data interchange with company network.

- Serial number scan with BARcode and QRcode reader.

- Acquisition of test parameters.

- Recording of test results on Excel file.

- Creation and eventual exportation of a .CSV file for each serial number, showing the results of the tests.

The bench is equipped with a generator for powering the motor controls, capable of supplying voltages between 15 and 30 Vdc with a power of 1600 VA.

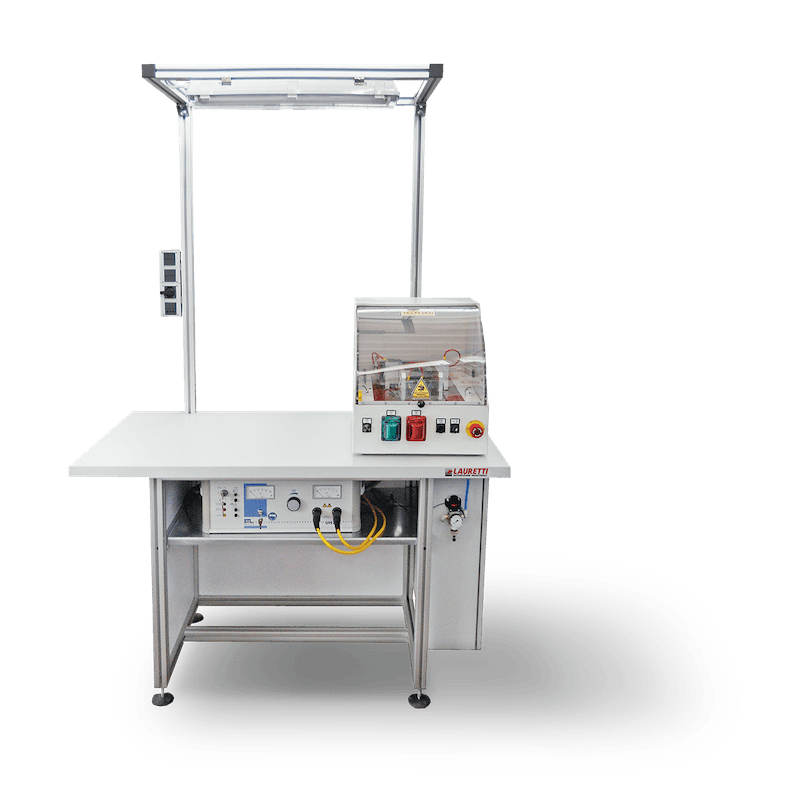

Test bench for thermal tests

Test bench for thermal tests on relays and motor protectors

Test bench for thermal tests

The bench is equipped with 2 static current generators that feature three scales 2 A - 12 A - 60 A to perform thermal tests on relays and motor protectors.

Management software features:

- Management of test types (recipes)

- Setting of test currents and test duration outside the recipes

- Setting the number of test cycles

- Storage of the following data in a database: product code, batch number, test date, operator name, intervention times of NC-NO contacts, contact switching delay, reset times, currents applied

- Exportation of data in CSV format

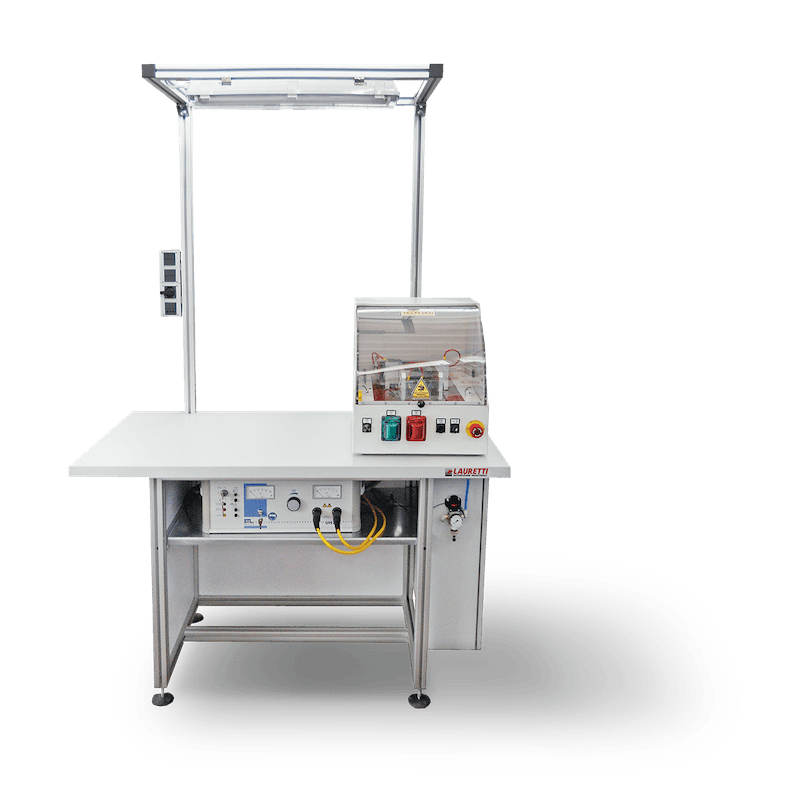

Test bench for thermal test

Test bench for thermal test on relays

Test bench for thermal test

Test bench for thermal test on relays

The bench is equipped with a current generator equipped with a voltage drop measurement system. This measure is managed by the management software.

Test bench for differential relays

Bench for testing differential relays

Test bench for differential relays

Test bench for testing differential relays

The bench is equipped with a single-phase current generator and an isolation transformer for powering the differential. The integrated management software was developed according to customer specifications.

Test bench for circuit-breakers accessories

Test bench for molded-case and air circuit-breakers accessories

Test bench for molded-case and air circuit-breakers accessories

Test bench for molded-case and air circuit-breakers accessories, equipped with 3 voltage power supplies and 3 current generators.

The test bench is equipped with an electric control panel, on whose door it has been positioned a panel with LEDs for checking the status of the auxiliary contacts. On the the panel are also installed 60 spring clamps for connecting terminals of the accessories.

Climatic Chamber

Climatic chamber for testing circuit breakers

Climatic Chamber

Climatic Chamber with single-phase corrent generator for testing circuit breakers.

Software functionalities:

• Setting the primary test current directly or gradually

• Setting unbalanced phases current

• Setting number of cycles

• Settting internal temperature directly or gradually

• Setting the fan speed

• Storing and exporting test data

• Visualizing alarms

Test bench for insulation tests

Test bench for insulation tests on molded-case switches

Test bench for insulation tests

The bench allows you to perform dielectric rigidity tests in a functional and safe way.

Test bench for counter panels

Test bench designed to test meter panels

Test bench for counter panels

The machine performs the following types of tests:

- Check the tightening torque of the screws;

- verification of the electrical continuity of the circuits;

- dielectric strength check;

- verification of counter functionality;

- verification of correct voltmetric socket connection;

- verification of power supply wiring and operation.

Test Bench for residual current releases

The bench performs functionality tests of the residual current releases and also tests the remote controls coupled with the circuit-breakers.

Test Bench for residual current releases

The bench performs functionality tests of the residual current releases, both loose and coupled with the respective circuit-breakers. In addition, the equipmemnt tests the remote controls coupled with the circuit-breakers.

The bench is also able to test undervoltage, opening and closing coils, both AC and DC.

Test bench for switch accessories

Test bench for electrical accessories on switches. The bench is able to test the functionality of the accessories installed inside the assembly.

Test bench for switch accessories

The machine allows you to perform various types of tests such as:

- minimum voltage coil operation;

- opening and closing operation;

- motor operation;

- Auxiliary contacts operation, etc.

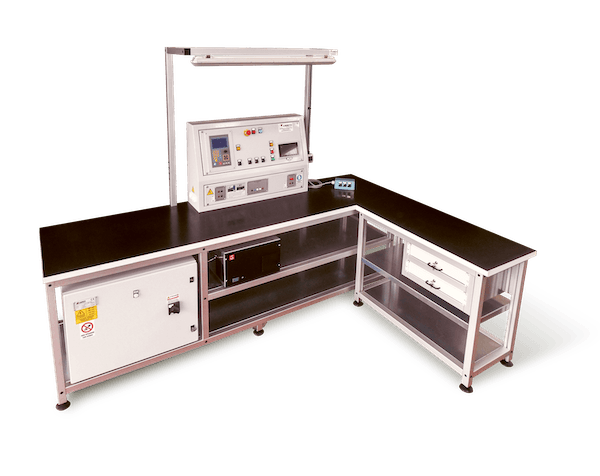

Thermomagnetic test bench BC02

Thermomagnetic test bench, able to carry out magnetic and thermal calibration tests on molded-case and open circuit-breakers, relays and motor protection switches.

Thermomagnetic test bench BC02

The benches are available in automatic and semi-automatic versions and can be customised according to the specific technical-production needs of the customer. They consist of one or more workstations designed to accommodate the product to be tested and can also be inserted into a production line.

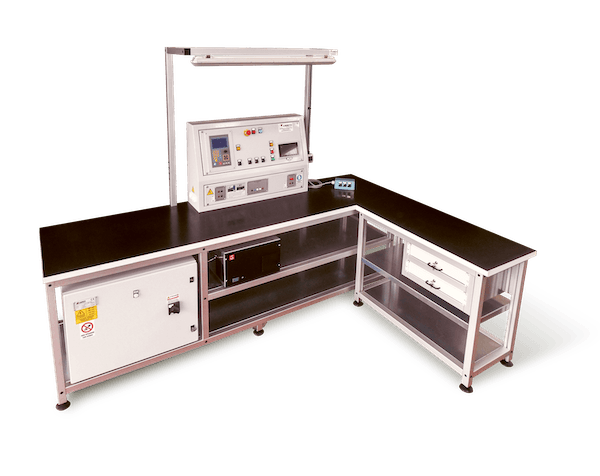

Insulation test bench BC03

Test bench for insulation tests on Tri and Four-pole circuit-breakers. The testing process can also be customized on other types of products.

Insulation test bench BC03

The bench allows you to perform dielectric rigidity tests in a functional and safe way, with a reduction in processing times related to the testing phase through the use of various independent housings for different test cycles.

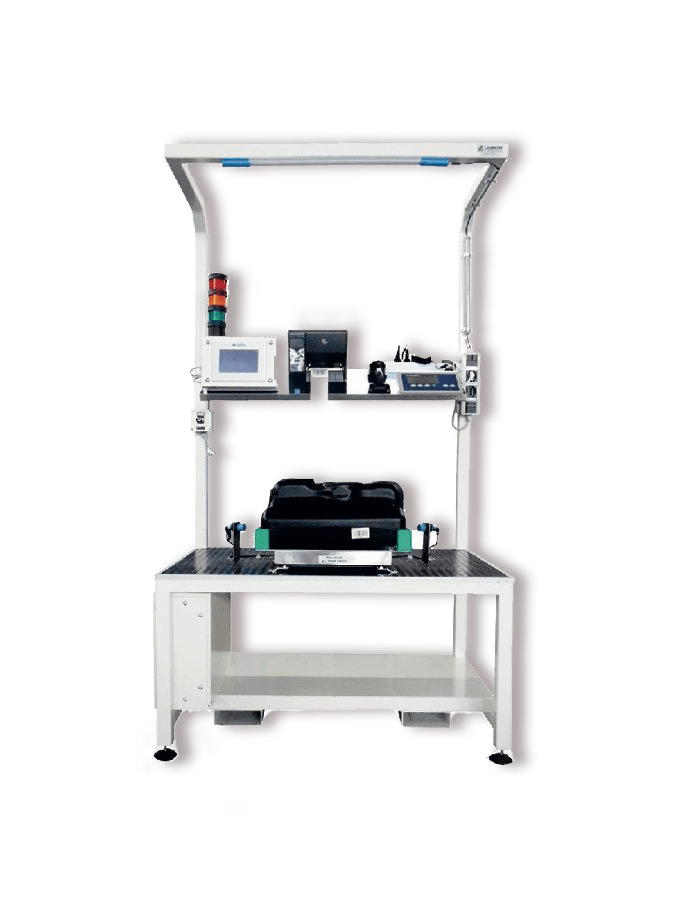

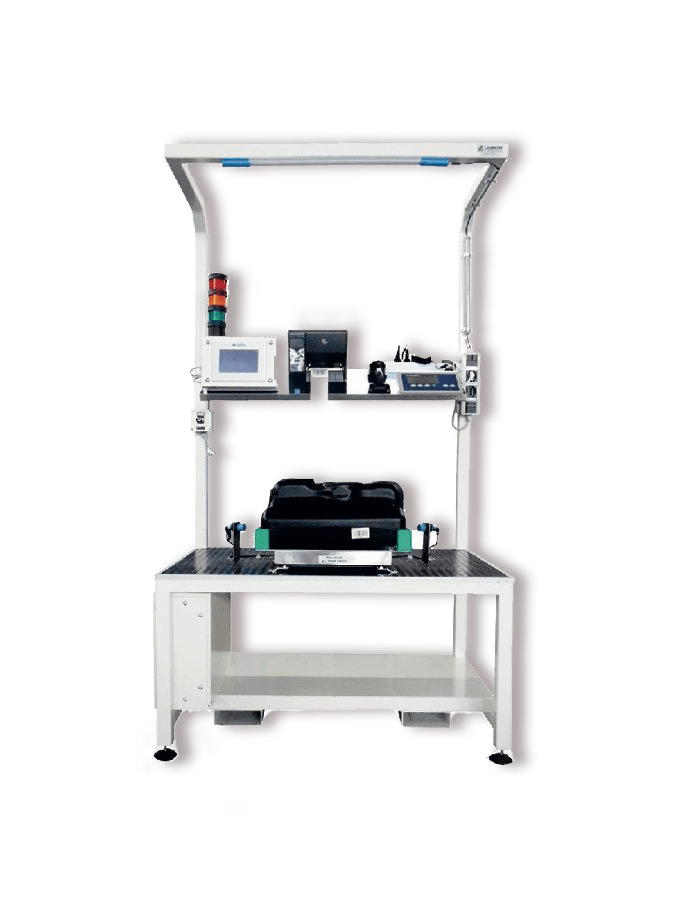

Weighing control bench for tanks

Bench suitable for performing control operations on automotive tanks.

Weighing control bench for tanks

The test bench performs weighing checks with the application of labels. The equipment has a supporting structure made of robust metallic carpentry.

All the devices are inserted and fixed on special shelves: the Mettler Toledo model scale, complete with relative position for the storage of the tank; bar code reader; Zebra ZT 230 label printer. The PLC management software is set up for management supervision connection.

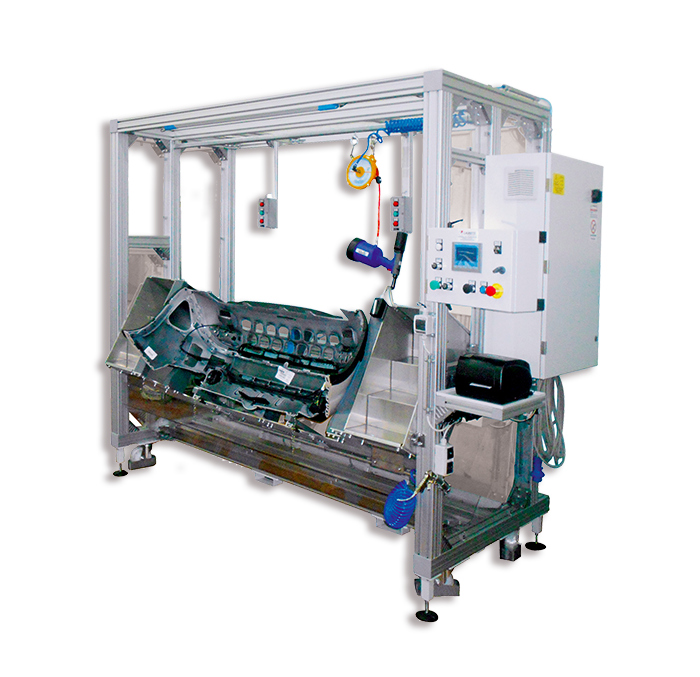

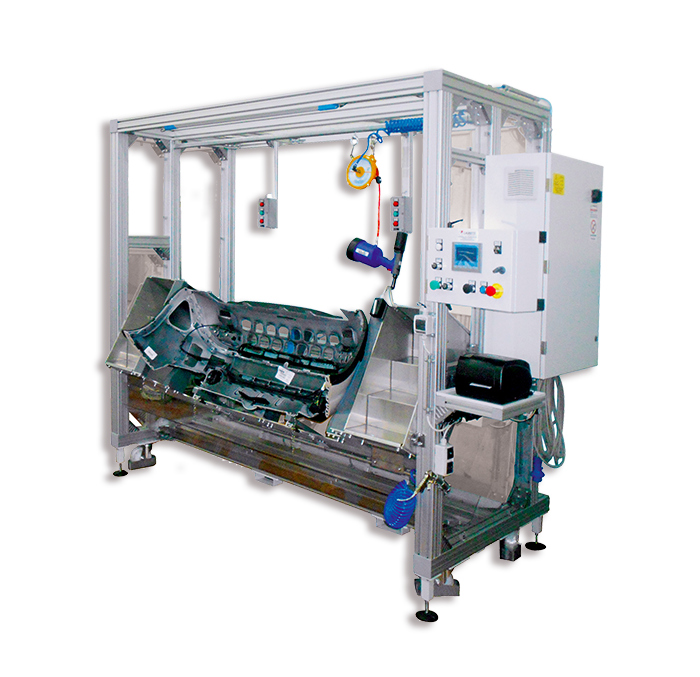

Calibration bench and actuator marking

Test bench designed to perform calibration and laser marking operations on actuators used in the Automotive sector.

Calibration bench and actuator marking

After the machine has carried out the calibration tests on the actuator with a positive result, it will carry out the marking of the piece using a laser marker.

For evacuation of the fumes produced during the marking phase, a vortex-type aspirator has been installed that will take the fumes and extract them via the customer's centralised system.

Headlight assembly and control bench

Test bench designed to perform assembly and control operations on fog lights.

Headlight assembly and control bench

The bench performs assembly and subsequent testing of the fog lights. It is equipped with scratch-resistant positioning equipped with sensors for detecting the presence of the piece.

The Fari TF22 control system instead consists of a mechanical / optical structure which, properly positioned and connected, allows the control and adjustment of the correct positioning of the fog lights.

Relay accessory test bench

Test bench designed to perform short reliability test on Automotive relays.

Relay accessory test bench

The bench performs the short reliability test on relays used in the automotive sector. It is structured to perform both mechanical durability tests with low load current (10mA max) but with high cycling frequency, which tests with high electrical load (50A max) and with low cycling frequency.

Contact us for information and quotations

Grazie per averci contattato. Ti risponderemo il più presto possibile.

Si è verificato un errore durante l'invio del messaggio. Riprova in un secondo momento.